Title: Deciphering the Selection Process: Choosing the Right Semi-Auto Biochemical Analyzer for Your Lab

Introduction:

In the dynamic landscape of laboratory diagnostics, semi-automatic biochemical analyzers play a pivotal role in streamlining workflows, enhancing efficiency, and ensuring accurate results. However, with a plethora of options available in the market, selecting the optimal analyzer for your laboratory can be a daunting task. In this comprehensive guide, we'll navigate through the key considerations, features, and specifications to help you make an informed decision when choosing a

semi-auto biochemical analyzer tailored to your lab's needs.

Understanding Semi-Auto Biochemical Analyzers:

Semi-auto biochemical analyzers are instrumental in performing a wide range of biochemical tests, including clinical chemistry, immunoassays, and enzyme-linked immunosorbent assays (ELISA).

Unlike fully automated systems, semi-auto analyzers require manual intervention for sample loading, reagent addition, and result interpretation, offering a balance between automation and user control.

These analyzers are suitable for laboratories with moderate testing volumes, offering flexibility, cost-effectiveness, and ease of operation.

Key Considerations in Selection:

a. Throughput and Capacity:

Assess your lab's testing volume and throughput requirements to determine the optimal analyzer capacity.

Consider factors such as sample throughput per hour, sample tray capacity, and the number of available test channels to ensure seamless workflow integration.

b. Test Menu and Versatility:

Evaluate the analyzer's test menu compatibility with the assays commonly performed in your laboratory.

Look for versatility in assay types, including chemistry panels, immunoassays, coagulation tests, and specialty assays, to accommodate diverse testing needs.

c. Analytical Performance:

Prioritize analyzers with high analytical accuracy, precision, and sensitivity to ensure reliable test results.

Consider parameters such as coefficient of variation (CV), linearity, and limit of detection (LOD) when assessing analytical performance specifications.

d. User Interface and Software:

Opt for analyzers equipped with intuitive user interfaces and user-friendly software interfaces to facilitate ease of operation and navigation.

Look for features such as touchscreen displays, customizable protocols, and built-in quality control functions for enhanced usability and efficiency.

e. Maintenance and Serviceability:

Evaluate the maintenance requirements and serviceability of the analyzer, including ease of cleaning, calibration, and troubleshooting procedures.

Consider the availability of technical support, service contracts, and spare parts to ensure uninterrupted operation and timely resolution of issues.

Notable Features and Specifications:

a. Sample Handling:

Look for analyzers with efficient sample handling systems, including automated sample dilution, mixing, and pipetting capabilities to minimize manual intervention.

Consider the compatibility with various sample types, including serum, plasma, urine, and cerebrospinal fluid (CSF), for comprehensive testing capabilities.

b. Reagent Management:

Assess the analyzer's reagent management system, including onboard reagent storage capacity, refrigeration options, and barcode identification for traceability and inventory management.

Look for analyzers with reagent-saving features such as low reagent consumption, onboard reagent stability, and automated reagent blanking to reduce operational costs.

c. Connectivity and Integration:

Consider analyzers equipped with connectivity options such as Ethernet, USB, and LIS (Laboratory Information System) interfaces for seamless data transfer and result reporting.

Look for compatibility with laboratory automation systems, middleware platforms, and electronic medical record (EMR) systems for streamlined workflow integration and data management.

d. Quality Control and Compliance:

Prioritize analyzers with built-in quality control functions, including internal quality control (IQC) and external quality assurance (EQA) capabilities, to ensure assay precision and accuracy.

Verify compliance with regulatory standards such as CLIA (Clinical Laboratory Improvement Amendments) and FDA (Food and Drug Administration) regulations to meet accreditation requirements and ensure patient safety.

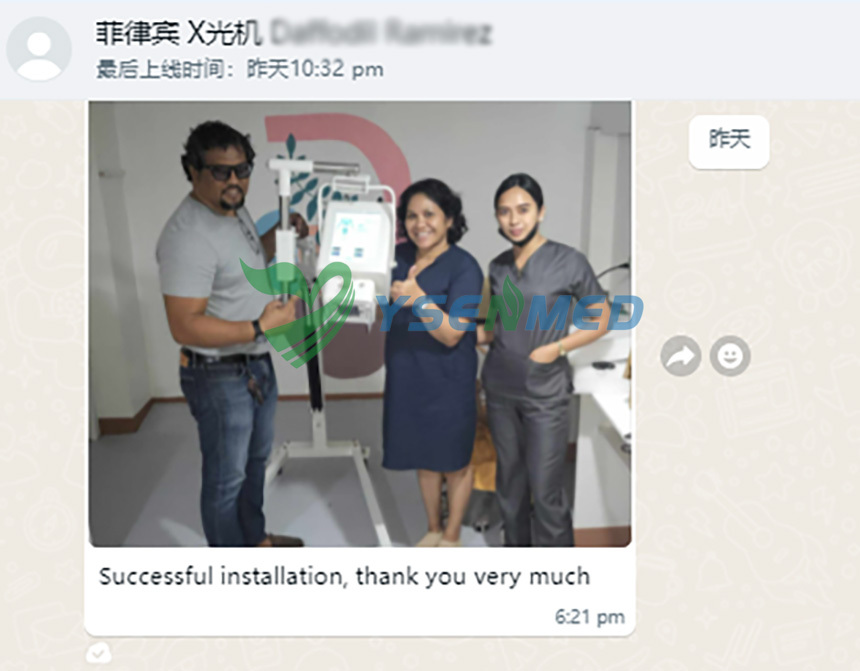

Case Studies and Testimonials:

Include real-world examples and testimonials from laboratories that have successfully implemented semi-auto biochemical analyzers.

Highlight the specific challenges faced, the solutions provided by the chosen analyzer, and the benefits realized in terms of efficiency, cost savings, and improved patient care.

Conclusion:

Conclude the article by summarizing the key points discussed and emphasizing the importance of selecting the right semi-auto biochemical analyzer tailored to your lab's specific needs.

Encourage readers to carefully evaluate the considerations, features, and specifications outlined to make an informed decision and maximize the efficiency and effectiveness of their laboratory operations.

By incorporating these insights and guidelines, you can navigate the complex landscape of semi-auto biochemical analyzers with confidence, ultimately selecting a solution that aligns with your laboratory's objectives and enhances overall performance and productivity.

Detailed Analysis of Key Considerations:

a. Throughput and Capacity:

Determine the expected daily workload of your laboratory to select an analyzer with an appropriate throughput capacity.

Consider factors such as sample volume, number of tests per day, and peak testing hours to ensure the analyzer can handle the workload efficiently.

Evaluate the sample tray capacity and loading mechanism to minimize manual handling and optimize workflow productivity.

b. Test Menu and Versatility:

Assess the clinical chemistry, immunoassay, and specialty test panels offered by the analyzer to meet the diverse testing needs of your laboratory.

Consider the availability of pre-packaged reagents, calibrators, and controls for the assays of interest to streamline inventory management and reduce operational complexity.

Look for analyzers with open-system architecture or customizable protocols to accommodate future test additions and emerging assay technologies.

c. Analytical Performance:

Review the analyzer's performance specifications, including accuracy, precision, linearity, and analytical measurement range, to ensure compatibility with your laboratory's quality standards and regulatory requirements.

Request validation data and proficiency testing results from the manufacturer to verify the analyzer's performance claims and compare them with established performance criteria.

d. User Interface and Software:

Evaluate the user interface design, menu navigation, and touchscreen responsiveness to assess the analyzer's ease of use and operator ergonomics.

Look for features such as customizable user profiles, predefined assay protocols, and on-screen prompts to streamline operator training and minimize errors.

Consider the availability of software updates, online tutorials, and technical support resources to facilitate ongoing user support and system optimization.

e. Maintenance and Serviceability:

Examine the analyzer's maintenance schedule, consumable requirements, and instrument uptime statistics to assess its reliability and operational efficiency.

Inquire about preventive maintenance protocols, calibration procedures, and troubleshooting guides to anticipate potential maintenance challenges and mitigate downtime risks.

Evaluate the manufacturer's service network, warranty coverage, and replacement parts availability to ensure timely support and cost-effective instrument maintenance.

In-Depth Exploration of Notable Features and Specifications:

a. Sample Handling:

Assess the analyzer's sample pipetting precision, sample volume range, and sample aliquoting capabilities to ensure accurate and reproducible results.

Evaluate the sample loading mechanism, sample probe design, and sample mixing functionality to minimize carryover contamination and sample-to-sample variability.

Consider the compatibility with sample tubes, microplates, and sample cup formats to accommodate different sample types and testing protocols.

b. Reagent Management:

Review the analyzer's reagent cartridge design, reagent stability, and onboard reagent inventory management system to optimize reagent utilization and minimize waste.

Evaluate the reagent loading process, reagent dispensing accuracy, and reagent barcode scanning functionality to ensure traceability and error prevention.

Look for analyzers with automated reagent priming, onboard reagent level sensors, and reagent expiry tracking features to streamline reagent management and reduce operator intervention.

c. Connectivity and Integration:

Explore the analyzer's data export options, including file formats, communication protocols, and compatibility with laboratory information systems (LIS) and electronic medical record (EMR) systems.

Verify the analyzer's connectivity to external devices such as printers, barcode scanners, and external monitors to facilitate result reporting and data exchange.

Consider the availability of remote monitoring capabilities, cloud-based data storage, and mobile applications to enhance accessibility and flexibility in data management and analysis.

d. Quality Control and Compliance:

Review the analyzer's built-in quality control features, including automated QC scheduling, QC result tracking, and QC data analysis tools to ensure assay accuracy and reliability.

Evaluate the analyzer's compliance with regulatory standards such as CLIA, FDA, and ISO (International Organization for Standardization) to meet accreditation requirements and ensure patient safety.

Inquire about the availability of validation documentation, proficiency testing programs, and audit trail functionalities to support regulatory compliance and quality management practices.

Conclusion and Call to Action:

Summarize the key considerations, features, and specifications discussed in the article, emphasizing their importance in selecting the right semi-auto biochemical analyzer for your laboratory.

Encourage readers to utilize the provided guidelines and insights to evaluate available options, request product demonstrations, and engage with manufacturers to make an informed decision.

Provide a call to action, such as contacting a sales representative, scheduling a product trial, or requesting a customized quote, to facilitate the decision-making process and initiate further exploration of potential analyzer solutions.

By incorporating detailed analyses of key considerations, features, and specifications, this article aims to empower laboratory professionals with the knowledge and insights necessary to navigate the complex landscape of

semi-auto biochemical analyzers and make well-informed decisions aligned with their laboratory's specific needs and objectives.